WSQ Implement Lean Six Sigma

Lean Six Sigma is an integrated set of methodologies that combines both traditional Lean and Six Sigma concepts to provide the necessary tools to address all aspects of quality, cost, and delivery. Lean Six Sigma is a powerful approach that allows organizations to achieve targeted value more quickly at the lowest possible cost, while aligning processes with customers.

At the end of the training programme, the learners will be able to apply strategies, methods and tools used

for developing and implementing lean six sigma project plans, such as:

1. Map and evaluate business process using Value Stream Mapping tool

2. Defines and establish the value flow

3. Identify and analyse non-value added process using VSM tool

4. Design, measure, evaluate and implement improvements

Introduction to Lean

– Identify a situation where lean can be a benefit

– Explain the benefits of going lean

– List and define five principles of lean

– List the eight types of waste and how to correct them

– Differentiate value-added work from waste

– Quantitatively assess your organisation’s lean readiness

– Determine product families that share common processes

Lean Culture

– Explain the importance of respect for people, change management, and continuous improvement in the lean philosophy

– Explain the forming, storming, norming, performing, and reforming stages of team development

– Conduct a kaizen event and fill in a kaizen report

– Explain the concept of jidoka, including line stop, operator flexibility, and poka-yoke

– List five criteria for choosing a lean pilot product family

Value Stream Mapping

– Explain how value stream mapping fuels continuous improvement

– Create a current-state map using standard icons

– Accurately calculate takt time to determine if a process can meet customer demand

– Incorporate value stream concepts to create a future-state map

Stability & Process Improvement

– Determine methods to achieve market demand stability

– Utilise three methods to level a value stream

– Give three methods to improve process stability

– Give three standard work components and the benefits of standard work

– Evaluate and reduce setup time using the 5S tool

– Explain how the six sigma methodologies apply to process stability

Just-in-Time

– Explain Just-in-Time

– Compare and contrast one-piece and batch flows

– Explain production cell varieties

– Explain kanban card line operations

– Level the schedule using takt time, one-piece flow, and heijunka

Measuring

– Compare lean to traditional accounting and measuring

– Create a profit and loss (P&L) statement for a value stream and compare to a standard cost P&L

– Create a performance alignment chart

– Explain seven lean measurements

– Explain how negative financial results may result from lean transformations

– Calculate lead time through production

Sustaining

– Describe three reasons for implementing DFMA

– Explain how to determine technical design priorities using a house of quality matrix

– Utilise cause and effect to determine required design controls using an FMEA

– List the seven quality control tools

– Utilise Plan-Do-Check-Act and six sigma DMAIC

– Create an action plan to implement and sustain lean principles in their organisation

This course adheres to the SSG Skills Framework <Value Analysis-PRE-VMA-4001-1.1> . Trainees who attended at least 75% of the scheduled class, demonstrated competency in the WSQ assessment, and participated during the scheduled class will receive the e-certificate with the aforementioned skills under the SSG Skills Framework.

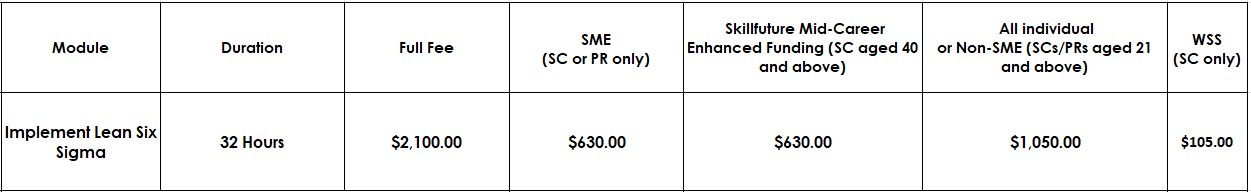

*Course fees before GST

**Funding is subjected to approval

Note that purchases of goods and services from GST-registered businesses will be subject to GST at 8% GST and it will be adjusted to 9% GST from 1st January 2024. The GST amount calculated will be based on full course fees.

This is an industry oriented programme and candidates should preferable possess the following:

• Diploma in any discipline and/or

• A minimum of 3 years working experience

• Language proficiency is English, at GCE N’ Level

An applicant must be at least 18 years of age on admission to the programme.

Terms of Use

AGREEMENT BETWEEN USER AND SMF CENTRE FOR CORPORATE LEARNING PTE. LTD.

SMF CENTRE FOR CORPORATE LEARNING PTE. LTD. (hereinafter referred to as the “SMF CCL”) Web Site is offered to you conditioned on your acceptance without modification of the terms, conditions, and notices contained herein. Your use of the SMF CCL Web Site constitutes your agreement to all such terms, conditions, and notices.

MODIFICATION OF THESE TERMS OF USE

SMF CCL reserves the right to change the terms, conditions, and notices under which the SMF CCL Web Site is offered, including but not limited to the charges associated with the use of the SMF CCL Web Site.

LINKS TO THIRD PARTY SITES

The SMF CCL Web Site may contain links to other Web Sites (“Linked Sites”). The Linked Sites are not under the control of SMF CCL and SMF CCL is not responsible for the contents of any Linked Site, including without limitation any link contained in a Linked Site, or any changes or updates to a Linked Site. SMF CCL is not responsible for webcasting or any other form of transmission received from any Linked Site. SMF CCL is providing these links to you only as a convenience, and the inclusion of any link does not imply endorsement by SMF CCL of the site or any association with its operators.

NO UNLAWFUL OR PROHIBITED USE

As a condition of your use of the SMF CCL Web Site, you warrant to SMF CCL that you will not use the SMF CCL Web Site for any purpose that is unlawful or prohibited by these terms, conditions, and notices. You may not use the SMF CCL Web Site in any manner which could damage, disable, overburden, or impair the SMF CCL Web Site or interfere with any other party’s use and enjoyment of the SMF CCL Web Site. You may not obtain or attempt to obtain any materials or information through any means not intentionally made available or provided for through the SMF CCL Web Sites.

USE OF COMMUNICATION SERVICES

The SMF CCL Web Site may contain bulletin board services, chat areas, news groups, forums, communities, personal web pages, calendars, and/or other message or communication facilities designed to enable you to communicate with the public at large or with a group (collectively, “Communication Services”), you agree to use the Communication Services only to post, send and receive messages and material that are proper and related to the particular Communication Service. By way of example, and not as a limitation, you agree that when using a Communication Service, you will not:

- Defame, abuse, harass, stalk, threaten or otherwise violate the legal rights (such as rights of privacy and publicity) of others.

- Publish, post, upload, distribute or disseminate any inappropriate, profane, defamatory, infringing, obscene, indecent or unlawful topic, name, material or information.

- Upload files that contain software or other material protected by intellectual property laws (or by rights of privacy of publicity) unless you own or control the rights thereto or have received all necessary consents.

- Upload files that contain viruses, corrupted files, or any other similar software or programs that may damage the operation of another’s computer.

- Advertise or offer to sell or buy any goods or services for any business purpose, unless such Communication Service specifically allows such messages.

- Conduct or forward surveys, contests, pyramid schemes or chain letters.

- Download any file posted by another user of a Communication Service that you know, or reasonably should know, cannot be legally distributed in such manner.

- Falsify or delete any author attributions, legal or other proper notices or proprietary designations or labels of the origin or source of software or other material contained in a file that is uploaded.

- Restrict or inhibit any other user from using and enjoying the Communication Services.

- Violate any code of conduct or other guidelines which may be applicable for any particular Communication Service.

- Harvest or otherwise collect information about others, including e-mail addresses, without their consent.

Violate any applicable laws or regulations.

SMF CCL has no obligation to monitor the Communication Services. However, SMF CCL reserves the right to review materials posted to a Communication Service and to remove any materials in its sole discretion. SMF CCL reserves the right to terminate your access to any or all of the Communication Services at any time without notice for any reason whatsoever.

SMF CCL reserves the right at all times to disclose any information as necessary to satisfy any applicable law, regulation, legal process or governmental request, or to edit, refuse to post or to remove any information or materials, in whole or in part, at the sole discretion of SMF CCL.

Always use caution when giving out any personally identifying information about yourself or your children in any Communication Service. SMF CCL does not control or endorse the content, messages or information found in any Communication Service and, therefore, SMF CCL specifically disclaims any liability with regard to the Communication Services and any actions resulting from your participation in any Communication Service. Managers and hosts are not authorized spokespersons of SMF CCL, and their views do not necessarily reflect those of SMF CCL.

Materials uploaded to a Communication Service may be subject to posted limitations on usage, reproduction and/or dissemination. You are responsible for adhering to such limitations if you download the materials.

MATERIALS PROVIDED TO SMF CCL OR POSTED AT ANY SMF CCL WEB SITE

SMF CCL does not claim ownership of the materials you provide to SMF CCL (including feedback and suggestions) or post, upload, input or submit to any SMF CCL Web Site or its associated services (collectively “Submissions”). However, by posting, uploading, inputting, providing or submitting your Submission you are granting SMF CCL, its affiliated companies and necessary sublicensees permission to use your Submission in connection with the operation of their Internet businesses including, without limitation, the rights to: copy, distribute, transmit, publicly display, publicly perform, reproduce, edit, translate and reformat your Submission; and to publish your name in connection with your Submission.

No compensation will be paid with respect to the use of your Submission, as provided herein. SMF CCL is under no obligation to post or use any Submission you may provide and may remove any Submission at any time at the sole discretion of SMF CCL.

By posting, uploading, inputting, providing or submitting your Submission you warrant and represent that you own or otherwise control all of the rights to your Submission as described in this section including, without limitation, all the rights necessary for you to provide, post, upload, input or submit the Submissions.

LIABILITY DISCLAIMER

THE INFORMATION, SOFTWARE, PRODUCTS, AND SERVICES INCLUDED IN OR AVAILABLE THROUGH THE SMF CCL WEB SITE MAY INCLUDE INACCURACIES OR TYPOGRAPHICAL ERRORS. CHANGES ARE PERIODICALLY ADDED TO THE INFORMATION HEREIN. SMF CCL AND/OR ITS SUPPLIERS MAY MAKE IMPROVEMENTS AND/OR CHANGES IN THE SMF CCL WEB SITE AT ANY TIME. ADVICE RECEIVED VIA THE SMF CCL WEB SITE SHOULD NOT BE RELIED UPON FOR PERSONAL, MEDICAL, LEGAL OR FINANCIAL DECISIONS AND YOU SHOULD CONSULT AN APPROPRIATE PROFESSIONAL FOR SPECIFIC ADVICE TAILORED TO YOUR SITUATION.

SMF CCL AND/OR ITS SUPPLIERS MAKE NO REPRESENTATIONS ABOUT THE SUITABILITY, RELIABILITY, AVAILABILITY, TIMELINESS, AND ACCURACY OF THE INFORMATION, SOFTWARE, PRODUCTS, SERVICES AND RELATED GRAPHICS CONTAINED ON THE SMF CCL WEB SITE FOR ANY PURPOSE. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, ALL SUCH INFORMATION, SOFTWARE, PRODUCTS, SERVICES AND RELATED GRAPHICS ARE PROVIDED “AS IS” WITHOUT WARRANTY OR CONDITION OF ANY KIND. SMF CCL AND/OR ITS SUPPLIERS HEREBY DISCLAIM ALL WARRANTIES AND CONDITIONS WITH REGARD TO THIS INFORMATION, SOFTWARE, PRODUCTS, SERVICES AND RELATED GRAPHICS, INCLUDING ALL IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE AND NON-INFRINGEMENT.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL SMF CCL AND/OR ITS SUPPLIERS BE LIABLE FOR ANY DIRECT, INDIRECT, PUNITIVE, INCIDENTAL, SPECIAL, CONSEQUENTIAL DAMAGES OR ANY DAMAGES WHATSOEVER INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF USE, DATA OR PROFITS, ARISING OUT OF OR IN ANY WAY CONNECTED WITH THE USE OR PERFORMANCE OF THE SMF CCL WEB SITE, WITH THE DELAY OR INABILITY TO USE THE SMF CCL WEB SITE OR RELATED SERVICES, THE PROVISION OF OR FAILURE TO PROVIDE SERVICES, OR FOR ANY INFORMATION, SOFTWARE, PRODUCTS, SERVICES AND RELATED GRAPHICS OBTAINED THROUGH THE SMF CCL WEB SITE, OR OTHERWISE ARISING OUT OF THE USE OF THE SMF CCL WEB SITE, WHETHER BASED ON CONTRACT, TORT, NEGLIGENCE, STRICT LIABILITY OR OTHERWISE, EVEN IF SMF CCL OR ANY OF ITS SUPPLIERS HAS BEEN ADVISED OF THE POSSIBILITY OF DAMAGES. BECAUSE SOME STATES/JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IF YOU ARE DISSATISFIED WITH ANY PORTION OF THE SMF CCL WEB SITE, OR WITH ANY OF THESE TERMS OF USE, YOUR SOLE AND EXCLUSIVE REMEDY IS TO DISCONTINUE USING THE SMF CCL WEB SITE.

TERMINATION/ACCESS RESTRICTION

SMF CCL reserves the right, in its sole discretion, to terminate your access to the SMF CCL Web Site and the related services or any portion thereof at any time, without notice. GENERAL To the maximum extent permitted by law, this agreement is governed by the laws of the State of Washington, U.S.A. and you hereby consent to the exclusive jurisdiction and venue of courts in King County, Washington, U.S.A. in all disputes arising out of or relating to the use of the SMF CCL Web Site. Use of the SMF CCL Web Site is unauthorized in any jurisdiction that does not give effect to all provisions of these terms and conditions, including without limitation this paragraph. You agree that no joint venture, partnership, employment, or agency relationship exists between you and SMF CCL as a result of this agreement or use of the SMF CCL Web Site. SMF CCL’s performance of this agreement is subject to existing laws and legal process, and nothing contained in this agreement is in derogation of SMF CCL’s right to comply with governmental, court and law enforcement requests or requirements relating to your use of the SMF CCL Web Site or information provided to or gathered by SMF CCL with respect to such use. If any part of this agreement is determined to be invalid or unenforceable pursuant to applicable law including, but not limited to, the warranty disclaimers and liability limitations set forth above, then the invalid or unenforceable provision will be deemed superseded by a valid, enforceable provision that most closely matches the intent of the original provision and the remainder of the agreement shall continue in effect. Unless otherwise specified herein, this agreement constitutes the entire agreement between the user and SMF CCL with respect to the SMF CCL Web Site and it supersedes all prior or contemporaneous communications and proposals, whether electronic, oral or written, between the user and SMF CCL with respect to the SMF CCL Web Site. A printed version of this agreement and of any notice given in electronic form shall be admissible in judicial or administrative proceedings based upon or relating to this agreement to the same extent an d subject to the same conditions as other business documents and records originally generated and maintained in printed form. It is the express wish to the parties that this agreement and all related documents be drawn up in English.

COPYRIGHT AND TRADEMARK NOTICES:

All contents of the SMF CCL Web Site are: Copyright © 2019 SMF CENTRE FOR COROPORATE LEARNING PTE. LTD. All rights reserved and/or its suppliers. All rights reserved.

TRADEMARKS

The names of actual companies and products mentioned herein may be the trademarks of their respective owners.

The example companies, organizations, products, people and events depicted herein are fictitious. No association with any real company, organization, product, person, or event is intended or should be inferred.

Any rights not expressly granted herein are reserved.

NOTICES AND PROCEDURE FOR MAKING CLAIMS OF COPYRIGHT INFRINGEMENT

Pursuant to Title 17, United States Code, Section 512(c)(2), notifications of claimed copyright infringement under United States copyright law should be sent to Service Provider’s Designated Agent. ALL INQUIRIES NOT RELEVANT TO THE FOLLOWING PROCEDURE WILL RECEIVE NO RESPONSE. See Notice and Procedure for Making Claims of Copyright Infringement.

Privacy Statement

SMF Centre for Corporate Learning Pte. Ltd. (hereinafter referred to as the “SMF CCL”) is committed to protecting your privacy and developing technology that gives you the most powerful and safe online experience. This Statement of Privacy applies to the SMF CCL Web site and governs data collection and usage. By using the SMF CCL website, you consent to the data practices described in this statement.

Collection of your Personal Information

SMF CCL collects personally identifiable information, such as your e-mail address, name, home or work address or telephone number. SMF CCL also collects anonymous demographic information, which is not unique to you, such as your ZIP code, age, gender, preferences, interests and favorites.

There is also information about your computer hardware and software that is automatically collected by SMF CCL. This information can include: your IP address, browser type, domain names, access times and referring Web site addresses. This information is used by SMF CCL for the operation of the service, to maintain quality of the service, and to provide general statistics regarding use of the SMF CCL Web site.

Please keep in mind that if you directly disclose personally identifiable information or personally sensitive data through SMF CCL public message boards, this information may be collected and used by others. Note: SMF CCL does not read any of your private online communications.

SMF CCL encourages you to review the privacy statements of Web sites you choose to link to from SMF CCL so that you can understand how those Web sites collect, use and share your information. SMF CCL is not responsible for the privacy statements or other content on Web sites outside of the SMF CCL and SMF CCL family of Web sites.

Use of your Personal Information

SMF CCL collects and uses your personal information to operate the SMF CCL Web site and deliver the services you have requested. SMF CCL also uses your personally identifiable information to inform you of other products or services available from SMF CCL and its affiliates. SMF CCL may also contact you via surveys to conduct research about your opinion of current services or of potential new services that may be offered.

SMF CCL does not sell, rent or lease its customer lists to third parties. SMF CCL may, from time to time, contact you on behalf of external business partners about a particular offering that may be of interest to you. In those cases, your unique personally identifiable information (e-mail, name, address, telephone number) is not transferred to the third party. In addition, SMF CCL may share data with trusted partners to help us perform statistical analysis, send you email or postal mail, provide customer support, or arrange for deliveries. All such third parties are prohibited from using your personal information except to provide these services to SMF CCL, and they are required to maintain the confidentiality of your information.

SMF CCL does not use or disclose sensitive personal information, such as race, religion, or political affiliations, without your explicit consent.

SMF CCL keeps track of the Web sites and pages our customers visit within SMF CCL, in order to determine what SMF CCL services are the most popular. This data is used to deliver customized content and advertising within SMF CCL to customers whose behaviour indicates that they are interested in a particular subject area.

SMF CCL Web sites will disclose your personal information, without notice, only if required to do so by law or in the good faith belief that such action is necessary to: (a) conform to the edicts of the law or comply with legal process served on SMF CCL or the site; (b) protect and defend the rights or property of Singapore Manufacturing Federation; and, (c) act under exigent circumstances to protect the personal safety of users SMF CCL, or the public.

Use of Cookies

The SMF CCL Web site use “cookies” to help you personalize your online experience. A cookie is a text file that is placed on your hard disk by a Web page server. Cookies cannot be used to run programs or deliver viruses to your computer. Cookies are uniquely assigned to you, and can only be read by a web server in the domain that issued the cookie to you.

One of the primary purposes of cookies is to provide a convenience feature to save you time. The purpose of a cookie is to tell the Web server that you have returned to a specific page. For example, if you personalize SMF CCL pages, or register with SMF CCL site or services, a cookie helps SMF CCL to recall your specific information on subsequent visits. This simplifies the process of recording your personal information, such as billing addresses, shipping addresses, and so on. When you return to the same SMF CCL Web site, the information you previously provided can be retrieved, so you can easily use the SMF CCL features that you customized.

You have the ability to accept or decline cookies. Most Web browsers automatically accept cookies, but you can usually modify your browser setting to decline cookies if you prefer. If you choose to decline cookies, you may not be able to fully experience the interactive features of the SMF CCL or Web sites you visit.

Security of your Personal Information

SMF CCL secures your personal information from unauthorized access, use or disclosure. SMF CCL secures the personally identifiable information you provide on computer servers in a controlled, secure environment, protected from unauthorized access, use or disclosure. When personal information (such as a credit card number) is transmitted to other Web sites, it is protected through the use of encryption, such as the Secure Socket Layer (SSL) protocol.

Changes to this Statement

SMF CCL will occasionally update this Statement of Privacy to reflect company and customer feedback. SMF CCL encourages you to periodically review this Statement to be informed of how SMF CCL is protecting your information.

Contact Information

SMF CCL welcomes your comments regarding this Statement of Privacy. If you believe that SMF CCL has not adhered to this Statement, please contact SMF CCL We will use commercially reasonable efforts to promptly determine and remedy the problem.

SMF Centre for Corporate Learning Pte Ltd has a Data Protection Policy which provides more information about how we collect, use and disclose your personal data. Please click the link below to know more.

https://www.smfccl.sg/privacy/

1. The candidate has the right to disagree with the assessment decision made by the assessor.

2. When giving feedback to the candidate, the assessor must check with the candidate if he agrees with the assessment outcome.

3. If the candidate agrees with the assessment outcome, the assessor & the candidate must sign the Assessment Summary Record.

4. If the candidate disagrees with the assessment outcome, he/she should not sign in the Assessment Summary Record.

5. If the candidate intends to appeal the decision, he/she should first discuss the matter with the assessor/assessment manager.

6. If the candidate is still not satisfied with the decision, the candidate must notify the assessor of the decision to appeal. The assessor will reflect the candidate’s intention in the Feedback Section of the Assessment Summary Record.

7. The assessor will notify the assessor manager about the candidate’s intention to lodge an appeal.

8. The candidate must lodge the appeal within 7 days, giving reasons for appeal together with the appeal fee of $108.00 (inclusive of 8% GST).

9. The assessor can help the candidate with writing and lodging the appeal.

10. The assessment manager will collect information from the candidate & assessor and give a final decision.

11. A record of the appeal and any subsequent actions and findings will be made.

12. An Assessment Appeal Panel will be formed to review and give a decision.

13. The outcome of the appeal will be made known to the candidate within 2 weeks from the date the appeal was lodged.

14. The decision of the Assessment Appeal Panel is final and no further appeal will be entertained.

15. Please click the link below to fill up the Candidates Appeal Form.